203. The East Palestine Ohio Train Wreck: a Study in Hysteria

The propagandists and the alternative media are both involved. The media, including some of our own, is our enemy. Stay focussed on true problems and ignore gaslighting.

by Frederick R Smith from Frederick R. Smith Speaks

I am a railroad manager who has been working in this industry since my teens. I have 45 years of experience with operations, facilities, and inspection. A colleague with similar depth collaborated in this evaluation. His specialty is supervising hazardous materials rail transportation.

On February 3, 2023, an eastbound Norfolk Southern (NS) freight train derailed in East Palestine, Ohio. Eleven of the fifty derailed cars contained high-hazard materials. Here is a history of similar accidents, train statistics, and the likely explanation for the accident.

All the information here is from public sources. Most of it is preliminary and subject to complete verification, and this is not an official report. The National Transportation Safety Board (NTSB) is forensically reconstructing the events, accident site, and critiquing the emergency response. See their website for updates.

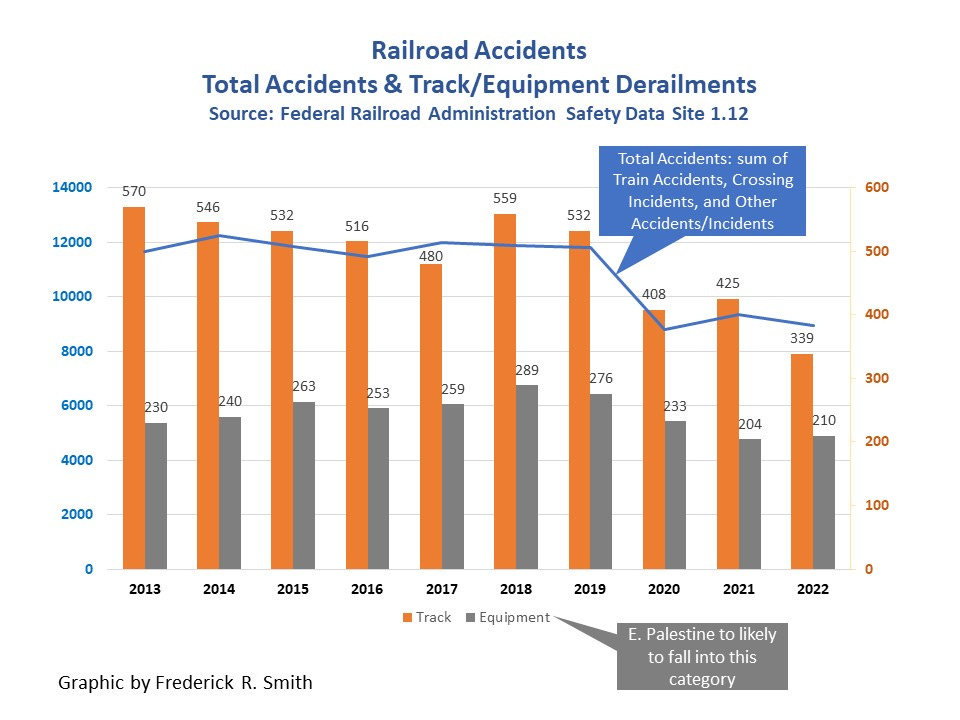

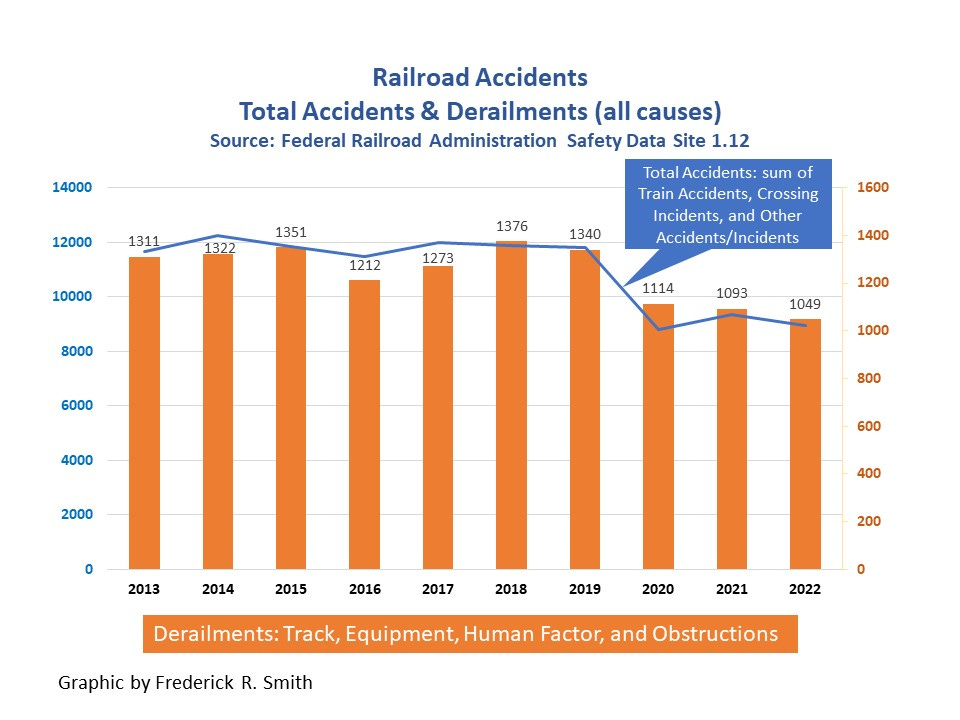

The legacy media, social media, and influencers are blowing this story up. For example, the claim has gone viral that there are twelve thousand derailments a year. This colossal figure is a misinterpretation of information from the Federal Railroad Administration Safety Data website.

Background

On February 3, 2023, at approximately 8:54 p.m., eastbound Norfolk Southern general merchandise train No. 32N, en route from Madison, IL to Conway, PA, derailed in East Palestine, OH, close to the Ohio – Pennsylvania state line. The train was operating on NS’s Fort Wayne in a 45 MPH speed zone at the time of the accident. The Fort Wayne line has two tracks through the area and annually hosts up to 100 million gross tons (MGT) of freight traffic. The Fort Wayne Line also hosts Amtrak intercity passenger trains.

The 150-car NS train No. 32N, pulled by three engines, consisted of 141 loaded cars and nine empty cars. The middle third of the 32Ns cars derailed (positions 23 through 74). Of the 50 derailed cars, 11 carried high-hazard materials and nine lower-level hazard products. No casualties were associated with the derailment and resulting pileup of equipment.

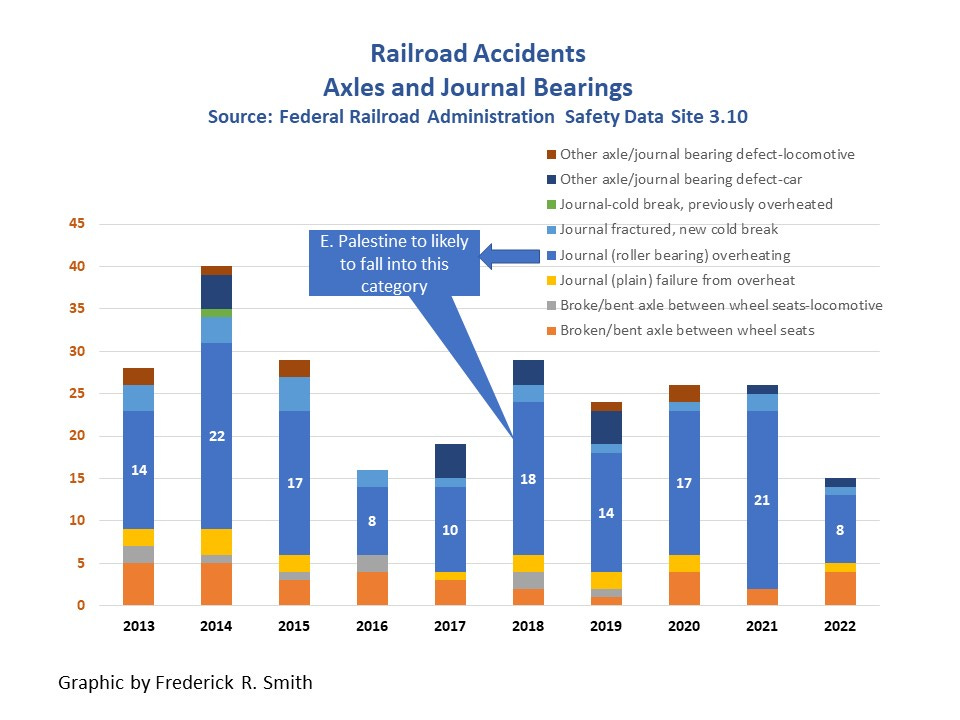

Approximately 20 miles west of the derailment site in Salem, Ohio, a security camera captured a shower of sparks from one car’s underside. Preliminary information indicates this event resulted from a failed roller bearing on one axle of one car in the train. The offending car remained on the track and thus did not exert excess force on the train. Because this car was a distance from the head of the train, the NS engineer, conductor, and conductor trainee situated at the front did not receive any indication of a mechanical failure for the 20 miles leading up to East Palestine.

Moments before the derailment, a video from a residence showed what appeared to be the wheel bearing of the problem car in the final stage of failure. That car triggered a wayside equipment detector (WED) to signal to the crew. Shortly after the WED alert, a train-initiated emergency brake application occurred. Under normal circumstances, when a train crew receives a WED indication, they usually place the automatic (train line) brake in “full-service reduction.” That will bring the train to a safe and controlled stop. This time, as the train started to pile up, that action caused the brake line to separate, which allowed the train brake pipe to exhaust its compressed air. It triggered the air brake valve on each car to send all of the compressed air from its associated air reservoir directly to the brake cylinders. In dire circumstances, an engineer can initiate an emergency brake application by manipulating the train line bake handle.

Due to the dynamic forces of the last third of the train, the middle one-third of the 32N’s cars derailed and bunched together in accordion fashion along a short track segment. After the front third of the train stopped, the crew uncoupled the engines from the train and moved east to safety. Eleven of the 50 derailed cars contained high-hazard materials, including vinyl chloride (5 cars), benzene residue (2 cars), butyl acrylate (1 car), isobutylene (1 car), ethylene glycol monobutyl ether (1 car), and ethylhexl acrylate (1 car). Additional cars carried low-level hazard combustible liquids. A fire burned for several days after the derailment. An EPA-maintained list of what the derailed rail cars were moving is available online.

Despite the pile-up and site burning for over two days, the tanks of the five cars containing vinyl chloride remained intact. However, emergency responders determined that the relief valve of one car had malfunctioned. To avoid a catastrophic explosion, officials decided to perform a controlled release and burned the contents. So after evacuating the danger zone, on February 6, hazmat crews pierced the cars with special devices that allowed the vinyl chloride to flow into a ditch for burning. The burn caused black clouds to form above the area, releasing phosgene and hydrogen chloride.

For details about the operations and decisions involved with controlled release, please see the following press conference by Ohio Governor Mike DeWine.

As detailed below, even if it were possible to release the product without a burn, mere contact with water alone would be dangerous.

Vinyl chloride properties

Vinyl chloride is a highly reactive and flammable gas that produces polyvinyl chloride (PVC), a common plastic material. Mixing vinyl chloride and water can be dangerous because vinyl chloride is highly soluble in water and can form an explosive mixture with air. This mixture can ignite or explode with a small spark or heat source. In addition to the risk of explosion, vinyl chloride is toxic and can cause a range of health problems, including damage to the liver, nervous system, and respiratory system. Exposure to vinyl chloride can also increase the risk of cancer, particularly liver cancer and angiosarcoma of the liver.

Water can react with the gas to form various byproducts depending on the conditions when it meets vinyl chloride. One of the most common byproducts is polyvinyl alcohol, a water-soluble polymer used in multiple applications, including adhesives, coatings, and textiles.

The reaction between vinyl chloride and water can produce other less desirable and potentially hazardous byproducts, including hydrochloric acid, a highly corrosive and toxic compound. This can cause severe skin and eye irritation and is harmful if inhaled or ingested. Phosgene, a poisonous gas used as a chemical weapon during World War I, is another potential byproduct of vinyl chloride and water reaction. This can cause severe respiratory problems, and small amounts can be lethal.

Electronically Controlled Pneumatic (ECP) train brakes

These advanced systems combine electronic and pneumatic technologies that precisely and efficiently control train braking. In typical fashion, the legacy press took the most inflammatory approach—a universal blame game. They even bashed the Trump administration for failing to promulgate an ECP mandate.

In an ECP system, each train car has an electronic control unit (ECU) that communicates with other ECUs via a wireless data link. When the train operator initiates a braking command, the lead ECU sends a signal to all the other ECUs on the train, activating the brakes on the other cars.

The ECP system uses compressed air to apply and release the brakes on each car. The lead ECU regulates the air pressure in the brake system to provide smooth and precise braking control. The ECP system can provide faster and more precise braking by using electronic commands to regulate air pressure than traditional pneumatic brake systems. Every car applies the brake at the same time, and that leads to much easier and more efficient train handling.

One of the critical benefits of ECP train brakes is that they can help reduce the risk of derailment from high dynamic train forces and other accidents by providing more precise and consistent control of the train’s braking. ECP systems are also more energy-efficient than traditional brake systems since they can release the air pressure in the brake system more quickly and with less waste.

In 2017, the government decided not to mandate ECP train brakes. Several factors drove that decision, including the cost of implementation, the compatibility with existing infrastructure, and the perceived benefits of the system compared to traditional brake systems.

Implementing the system would have incurred high new equipment costs and extensive training for train operators and maintenance personnel. It would have significantly burdened many railroads, particularly smaller operators.

ECP brakes would not have prevented this accident, for the failed journal bearing was likely the cause. However, ECP might have somewhat mitigated the pileup because such a system more effectively dissipates the dynamic push from all the train cars when in braking mode.

If these brakes had been mandated, NS train No. 23N would not have been required to use the system. “High-hazard flammable trains,” according to the 2014 Rail Safety Improvement Act, are defined as a single train transporting 20 or more tank cars loaded with a Class 3 flammable liquid. NS 23N had only three such train cars. Thus, it was not a high-hazard flammable train and would not have been affected by these rules.

Precision Scheduled Railroading (PSR)

PSR is a business model and operating strategy for freight railroads developed by rail executive E. Hunter Harrison (1944-2017) in the 1990s. PSR aims to increase the efficiency and profitability of railroads by streamlining operations, reducing costs, and improving service reliability. However, there are problems with PCR, and the East Palestine derailment spurred interest in the possibility of this operational model being a factor.

At its core, PSR focuses on two fundamental principles: reducing operating costs and improving asset utilization. The idea is to run fewer, longer trains with more consistent schedules, reducing idle time and optimizing train speed and routing. PSR seeks to eliminate waste and improve efficiency in every aspect of the railroad’s operations, from train movements to maintenance to workforce management. The goal is to create a more reliable, predictable, cost-effective rail service that meets customers’ needs while improving the railroad’s bottom line.

One critical feature of PSR is the operation of “very long trains” that avoid stopping, adding, or removing cars. Under PSR, railroads aim to operate more efficiently and reduce the time and expense of assembling and disassembling trains. PSR represents a significant shift in railroad operations, focusing on efficiency, reliability, and customer service. While the model has been controversial and has faced criticism from some quarters, many railroads have adopted PSR in recent years. It has improved their performance and competitiveness in this rapidly changing industry.

While PSR can bring benefits such as improved service and reduced congestion, it has raised safety concerns, including:

Reduced staffing levels. PSR often involves reducing staffing levels to cut costs, which can lead to a shortage of experienced workers, increasing the risk of accidents.

Increased employee workload. PSR can increase workloads as workers do more with fewer resources. That can lead to fatigue, stress, and reduced concentration, increasing the risk of accidents.

Reduced maintenance. PSR may prioritize the movement of trains over the maintenance of infrastructure and equipment. That can result in a reduced focus on safety-critical maintenance activities, such as track inspections and repairs, which could increase the risk of derailments or other accidents.

Increased train speeds. PSR can lead to increased speed to move more freight quicker. While faster speeds can reduce transit times, they also increase the risk of accidents, particularly at rail crossings or in areas with curves or steep grades.

Reduced safety redundancies. PSR can lead to eliminating safety redundancies, such as using manned helper locomotives or requiring two crew members in the cab. This can increase the risk of accidents, particularly in medical emergencies or other issues requiring immediate attention.

Very long trains can impact the intersections between roads and railway tracks (highway-rail grade crossings). Road users experience increased risk and longer delays. Here are some very long train issues:

Highway rail grade crossings. Trains take longer to pass through grade crossings. Road users and emergency responders must wait. This can increase the risk of collisions, especially if impatient drivers attempt to cross the tracks while a train is still passing.

Train handling. Trains require longer stopping distances, which may be an emergency issue. This can increase the risk of collisions or other accidents.

Longer delays. Trains may require several minutes to pass through grade crossings, which results in longer waits for road users, particularly during peak traffic. That can impact the productivity and efficiency of businesses located near grade crossings, as well as the quality of life of nearby residents.

Traffic congestion. Long delays at grade crossings can result in traffic congestion, especially if multiple grade crossings are nearby. That can impact the movement of goods and people and increase costs for businesses and individuals.

The official investigation is ongoing, so it is inappropriate to speculate if PSR was a factor in the East Palestine derailment. NS 23N had 150 cars, so it was mid-range and not one of the longest trains. Railroads operate much longer ones that are 200 cars or more and up to two miles long.

Here are a few derailments with functional similarities to this accident

Decatur, Illinois - June 29, 1974. A train carrying hazardous materials derailed and released toxic gas, causing the evacuation of more than 5,000 residents and hospitalizing more than 200 people.

Waverly, Tennessee - February 24, 1978. A train with propane cars derailed and exploded, killing 16 people and injuring dozens more.

Minot, North Dakota - January 18, 2002. A train carrying hazardous materials derailed and released toxic chemicals, causing the evacuation of nearby residents. The accident killed one person, caused serious injuries to 11 more (including both of the train's crew members), and caused minor injuries to 322 others.

New Brighton, Pennsylvania - February 6, 2006. A train transporting various hazardous materials, including chlorine and molten sulfur, derailed. The release of toxic gas prompted the evacuation of more than 1,000 nearby residents.

Paulsboro, New Jersey - November 30, 2012. A freight train carrying hazardous chemicals derailed. Four cars carrying vinyl chloride ruptured and leaked into the air. The accident resulted in the evacuation of over 800 nearby residents. Over 70 people were treated at local hospitals for respiratory problems, eye irritation, and other symptoms.

Casselton, North Dakota - December 30, 2013. A train carrying crude oil derailed and caught fire, causing the evacuation of nearby residents.

Lynchburg, Virginia - April 30, 2014. A train carrying crude oil derailed and caught fire, causing the evacuation of nearby residents.

Mount Carbon, West Virginia - February 16, 2015. A train carrying crude oil derailed and exploded, causing a massive fire that burned for several days.

Mosier, Oregon - June 3, 2016. A train carrying crude oil derailed and caught fire, causing the evacuation of nearby residents.

Graettinger, Iowa - March 10, 2017. A train carrying ethanol derailed and caught fire, causing the evacuation of nearby residents.

Hyndman, Pennsylvania - August 2, 2017. A train carrying hazardous materials derailed and caught fire, causing the evacuation of nearby residents.

Rail safety has improved

After the East Palestine derailment, many in the legacy media, social media, and influencers claimed “12 thousand derailments per year.” That colossal figure (33 daily) stems from uninformed glances at the Federal Railroad Administration Safety Data Site.

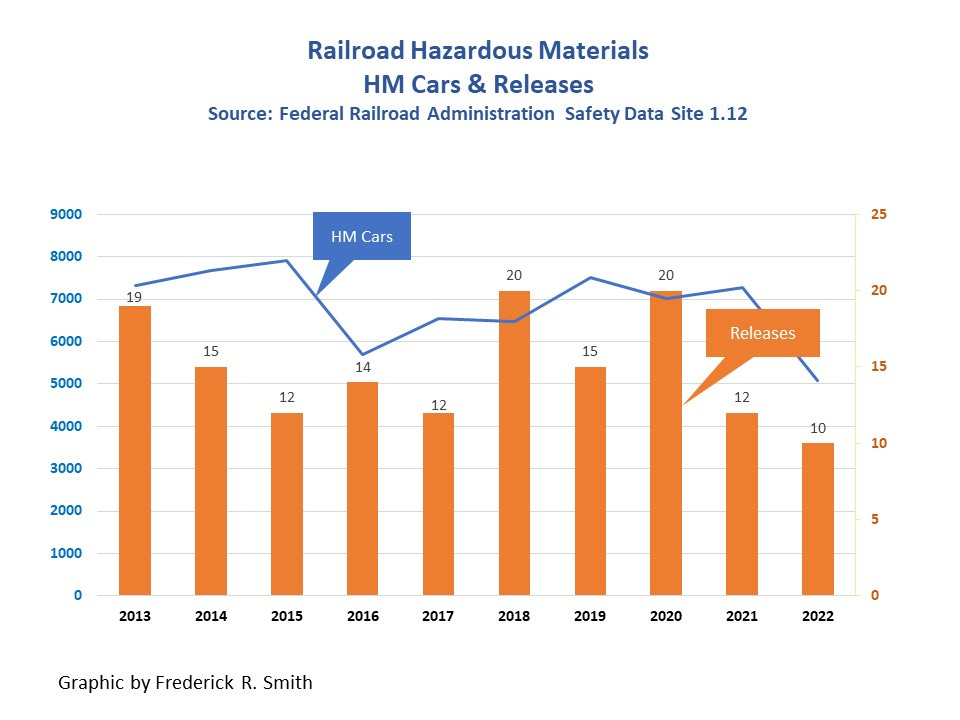

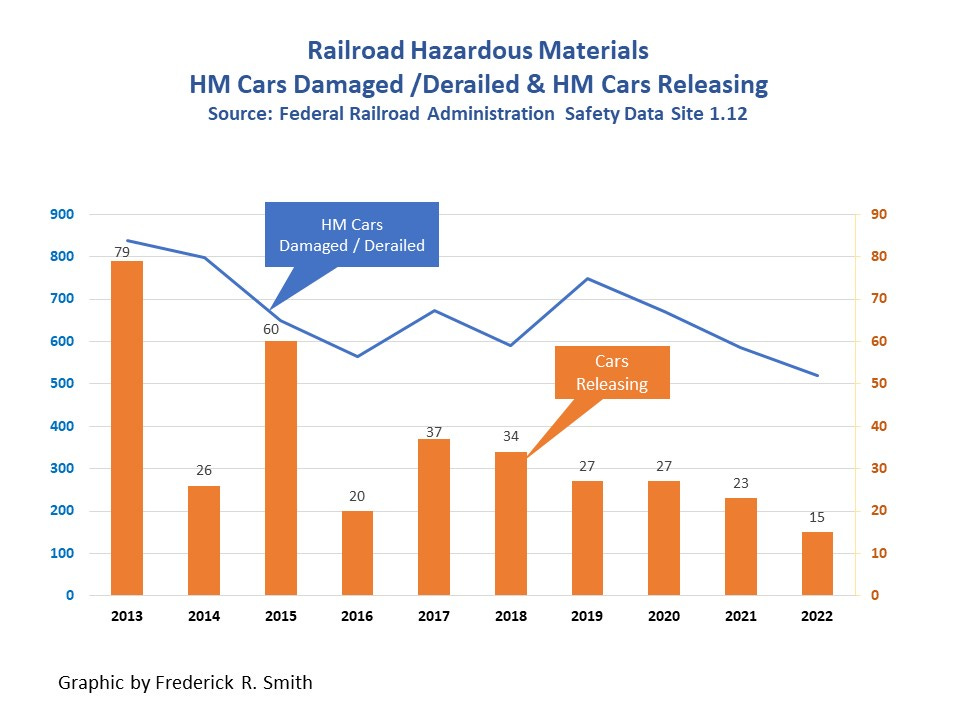

The “12 thousand figure” is the total of all reportable accidents and incidents, such as grade crossing collisions, trespasser fatalities, train collisions, employee fatalities, hazardous materials releases, and other accidents. In 2022, there were 1,049 derailments that average to under three a day. Based on most current data, the following graphs clarify US train accidents related to the East Palestine wreck.

Journalists were always irresponsible, but they are worse now

In our modern age, their stories are designed to confuse, frighten, and intimidate us. The ridiculous theories include the following:

A tie-in to the plot of the little-known 2022 motion picture White Noise includes a cataclysmic train accident that casts a cloud of chemical waste. The fictional Ohio town faces an “Airborne Toxic Event” that forces a massive evacuation.

A lawyer representing plaintiffs who filed a lawsuit after the train derailment in East Palestine, Ohio, alleged that some town residents might “already be undergoing DNA mutations.”

Claims that the burn-off may have caused the “largest dioxin plume in world history.”

A local broadcast station claimed that saboteurs likely perpetuated this accident.

The list goes on. Hopefully, this essay decreases speculation. I do not intend nor have the expertise to debate other issues, particularly the potential environmental and health issues for nearby residents. It is up to the NTSB and other trusted professionals to reconstruct this accident forensically, determine ecological and health impacts, and implement corrective measures. The Doomberg essay cited below is an excellent primer about the chemical hazards associated with this wreck.

Yoho comment: Just as air travel is phenomenally safer than driving, accidents during rail transport are a fraction of trucking’s. The substances involved in this crash are too dangerous to place in trucks and on our roads, so rail transport is used. Hazardous materials are a staple of modern commerce, and we need them to maintain our standard of living. This accident is a statistical outlier but not unexpected with our massive economy that transports everything imaginable over millions of miles. Trains are safe, and there is no benefit without risk.

Resources

Railroaded by Doomberg ~ comprehensive and well-written

Federal Railroad Administration safety data site

2023 Ohio Train Derailment by Wikipedia - comprehensive and well-written

With all due respect, this is supposed to make the residents of East Palestine feel better? Make everyone east of the Mississippi feel better? Feel healthier? Feel safer? Because what EVERYONE saw with their eyes and feel with their irritated skin and their hacking coughs and witnessed the dead marine wildlife, was all just a media psyop? Am I missing something here?

Sadly, and I don't understand why, this article is a study in obfuscation.

THE WHOLE ISSUE IS SOLELY ONE OF ***DIOXIN***. One 5 grain tablet of dioxin would give a lifetime max dose to 32,000 people. Yet you say nothing. Why? You only note "Claims that the burn-off may have caused the “largest dioxin plume in world history... " and then, fantastically, SAY NOTHING ABOUT IT, when you obviously know that open air burning in atmosphere (oxygen, moisture) creates dioxin.

*********THIS ARTICLE IN SCIENTIFICALLY AND INTELLECTUALLY DISHONEST************

Shame on you for this, or at minimum, NOT doing your homework